RIM Molding Services

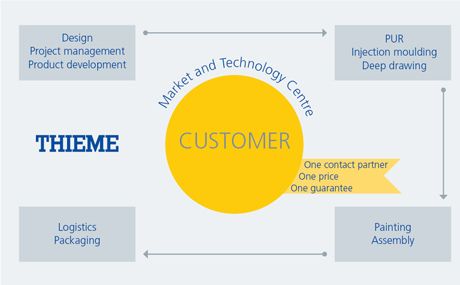

Thieme Corporation is a full service RIM molding provider offering exceptional program management, project engineering and delivered molded product to your assembly systems. Thieme Corporation engages with our customers in the earliest phases of design so we can provide design experience, optimize cost efficiency and mitigate error and risk in the delivery of your molded products. We are proud to offer the following services:

Project Management:

No matter where Thieme joins the part design process for your product assembly, Thieme will assign a project manager, designer and commercial program manger to your account. This same team will guide your RIM project from start to finish.

Product/Part Design Assistance

Your Thieme team has over 45 years of design experience in RIM parts and Rim tooling. Rest assured that we will incorporate as many cost reduction, risk mitigation and quality features possible into your part design and optimize it for RIM production.

RIM feasibility studies

Each part that is reviewed by Thieme goes through an extensive RIM Feasibility study to ensure the design, function and performance of the part/assembly will be suitable for the RIM process.

Tool Design

Thieme has been designing Rim tooling for over 40 years and incorporates many company driven innovations to give you a RIM tool that is guarantee to be of the latest design/rim technology. We always internalize out tool designs as a step to guarantee the part is right the first time, every time.

Simulation and FEA Analysis

In many situations, analysis needs to be performed to ensure moldability, part stress and performance. In some cases, Thieme will perform these analyses to ensure your part and our tool design perform to the optimum standard.

Prototype

Thieme Corporation offers a full line of prototyping ideas prior to production including, stereo lithography, cast urethane models, FRP & PUR block mock ups.

Production Molding

Thieme Corporation is first and foremost a production RIM molder. We have the capability to mold many types of systems and various levels of production including small annual runs of 200 up to annual runs of hundreds of thousands.

Painting

Thieme Corporation in association with our painting partner, provides world class finishing systems for your parts including flat, low gloss, texture and high gloss finishes for parts up to 10’ x 8’ x 3’.

EMI Shielding

In parts requiring electrostatic protection, shielding and electro conductivity, Thieme offers EMI shielding through our paint finishing services. The most complex masking treatments can be achieved.

High Level Assembly (HLA) Operations:

In addition to manufacturing your plastic covers, housings and enclosures, Thieme Corporation performs high level assembly operations including component assembly, wiring harness, cabling, laser mounting, control panel mounting and other sensitive assembly operations. This is a value added service that can lower your assembly costs when the Thieme enclosures arrive to your assembly line ready for installation.

Kitting and Logistics:

Thieme provides kitting and full logistics for all parts including those that are not made of rim. Specialty line shippping racks are designed for your assembly parts in your assembly line order.

Gage & Check Fixtures:

Thieme builds gage and check fixtures in cases when such are required. We take a no nonsense approach to ensure the gage/fixture is easy to use, is of low cost and performs correctly for the life of the program.

Shipping:

Thieme provides warehousing space and prepares shipments to meet the critical demands of transcontinental shipping requirements. We take pride in our on-time shipping record.