RIM Molding PUR Materials

PUR Materials

At Thieme, we use the finest, top-quality PUR Material systems to satisfy a wide range of performance requirements, especially when it comes to plastic RIM molding.

Thanks to the flexibility, diversity, and versatility of PUR molded parts, we can easily and quickly satisfy an array of customer-specific requirements.

Our PUR material systems are manufactured for medical, scientific, laboratory, agricultural, automotive, heavy equipment and various other industrial markets.

Typical PUR Applications

When it comes to typical applications of PUR materials, these include:

- Housings

- Enclosures

- Covers

- Panels

- Doors

- Functional, structural parts of all sizes, shapes, and types

- Automotive safety-relevant parts such as bumpers, spoilers, and trim.

- Automotive auxiliary parts such as special materials for handling containers for logistics, and part holders.

In case you need a complete system made of PUR materials, Thieme has the right tools, materials, and expertise to deliver products of the highest quality. From the initial meeting and project presentation to full delivery, our professional and friendly experts will be with you every step of the way.

PUR Material Systems

At Thieme, we mold PUR material systems of different rigidity degrees to satisfy a range of different applications. The reason why we chose polyurethane is simple – there is no other material that so ideally and perfectly combines function, ergonomics, and aesthetics like polyurethane.

We mold the following systems:

- PUR Integral Hard Sandwich Foam (Baydur 726 PUR)

- PUR Compact Rigid Foam (Prism CM-200 PUR)

- PUR Flexible Rigid Foam (Bayflex PUR Family, including 110-50 and XGT)

With over 40 years of experience in the business and countless projects under our belt, we offer innovative, top-quality, excellent PUR molding services that will increase your competitiveness. Contact us today to determine your requirements and find the best deal.

Determining which type of polyurethane pur material system will work best for an application will depend on the degree of rigidity is needed for the application. The degree of righty will place it one of two categories; a rigid polyurethane or an elastomeric.

A rigid PUR material system has a higher flexural modulus and degree of hardness. Typical properties associated with rigid polyurethanes are good chemical resistance, electrical properties and acoustical thermal insulation.

An elastomeric polyurethane PUR material system is usually used in applications needing superior impact strength. They have good toughness and dimensional stability under a variety of temperature ranges (to -30 degrees Fahrenheit). Even under these temperature loads, the elastomeric polyurethanes retain excellent physical properties such as excellent abrasion, corrosion resistance and wear resistance.

Within these two categories (rigid and elastomeric) there are three (3) classifications of polyurethane (PUR) material systems; Solid PUR, Foamed PUR and structural composite PUR.

Thieme Corporation molds PUR material systems. Polyurethane is the material used for all of our part applications. Virtually no other material combines aesthetics, ergonomics and function in such an ideal form.

Generally, polyurethane PUR material systems from the leading raw material manufacturers Bayer and BASF are used at Thieme. The materials are purchased as preformulated systems and are processed into high-quality parts.

Thieme Corporation consistently molds the following polyurethane PUR material systems:

PUR Integral Hard Sandwich Foam (IHSF)

+ Sandwich-style design with high inherent rigidity

+ Extraordinary design flexibility

+ Good thermal and acoustic insulation properties

+ Used for thick and thin walled parts

+ Excellent surface finish

+ Structural design intent

+ UL 94 Rated V-0

PUR Compact Rigid Foam (Prism)

+ Compact structure and high impact strength

+ Mimics performance of injection molding type wall sections

+ Excellent stiffness to weight ratio

+ Good heat deflection temperature

+ Impact resistant Excellent surface quality for finishing

+ Parts as large as 10’ x 8’ x 3’ in a single shot

+ UL 94 Rated V-0

PUR Flexible Rigid Foam (Flex)

+ High impact strength also at low temperatures extraordinarily durable

+ Aesthetics possible by means of structured tool surfaces

+ Excellent surface quality for finishing

+ Wide range of flexural moduli

+ UL 94 Rated HB

PUR Casting System (GS)

+ The material for mechanically and chemically stressed functional parts

+ Alternative to grey cast iron or steel

+ UL 94 Rated V-0

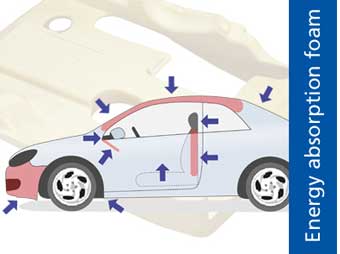

PUR Energy Absorption Semi Rigid Foam (EA)

+ Kinetic energy is converted into deformation energy

+ Can be optimally used for the most diverse requirements

+Low tendency for squeak and rattle

+ Passive passenger protection for all vehicle areas

PUR Sound Absorbing Flexible Foam (SA)

+ Large Part Moldability and Backfilling

+ Can be used for the most diverse requirements

+ Exceptional sound absorption properties

Solid Polyurethane Systems

Solid polyurethane pur systems don’t include blowing agents resulting in a solid rigid or elastomeric solid plastic. These elastomeric systems are typically used for automotive trims, fascias, bumpers and other parts in the construction, automotive, recreational and agricultural industries. The solid rigid systems are usually used to mold thin walled parts (3-6mm) resulting in applications such as business machine covers, medical device covers, large format parts and other parts similar in design and use as typical injection molded parts.

Structural Composite PUR Systems

These polyurethane systems are foamed systems and can variable wall sections. These systems have extremely high stiffness and high impact strength due to additives of glass or glass mats in the molding process. Typical applications include panels, shelves, load bearing parts and housings.

Foamed Polyurethane Systems

- Higher density skins with lower density microcellular cores in a sandwich like composition

- Ability to design parts with variable wall sections (up to 2”) without sink or distortion in the part

- Useful for load bearing applications

- Allows designers to integrate the structure of a housing with the aesthetic needs of the part in a single part (sometimes eliminating the need for sheet metal sub assemblies for mounting the covers to)

- Applications include but are not limited to business machine covers, medical device enclosures and housings, device bezels, ski’s, car spoilers and many more.